No Stopping From The First Second

Founded in 2010, TECSAFE has become a leading manufacturer of foam inserts for storage, protection, transport and packaging applications.

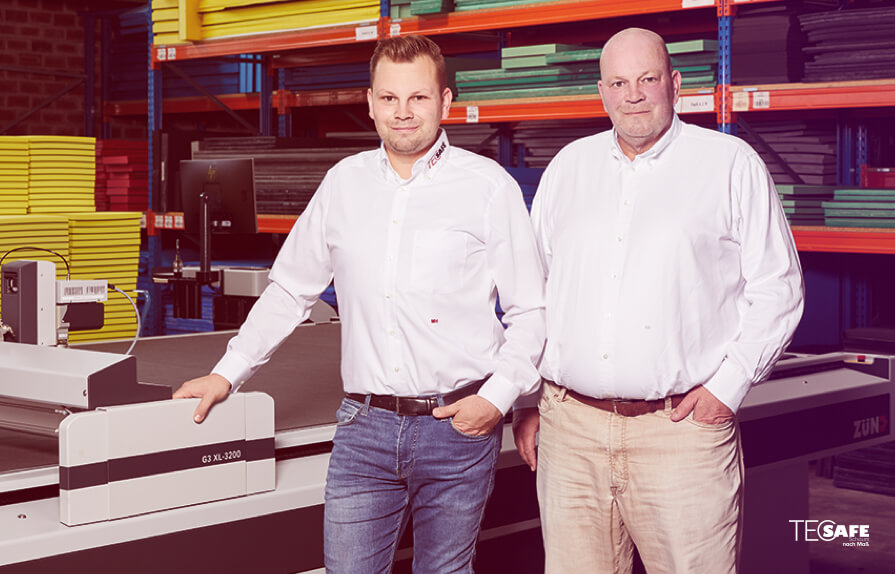

Father and son Knut and Maximilian Hermes started out ten years ago with a small-scale operation producing foam inserts. We now have two production sites and a customer base that includes over 100 manufacturers, retailers and associations. The steadily growing demand from our customers is currently being handled by a workforce of over 40. Germany’s FOCUS magazine has already awarded us the accolade of “Growth Champion” no fewer than three times.

Our success is no accident. From the very outset, our family company has focused on technical innovation and the highest quality standards. This benefits our customers in the form of extremely fast delivery times, industry-leading online configuration options and superior product quality. Throughout our journey, we have maintained our passion for bespoke solutions and still enjoy being able to support our customers with tailored storage and packaging ideas.

Our Philosophy: Maximum Quality and Rapid Realisation

TECSAFE Means Quality & Innovation

qualityPremium Inside And Outside

That is why TECSAFE deliberately chooses to use materials of the highest quality. Over the years, we have realised that, despite the associated costs, quality really does pay for itself at the end of the day. Our products combine an above-average service life with excellent robustness in everyday use. Another feature of the raw material is the way it is manufactured.

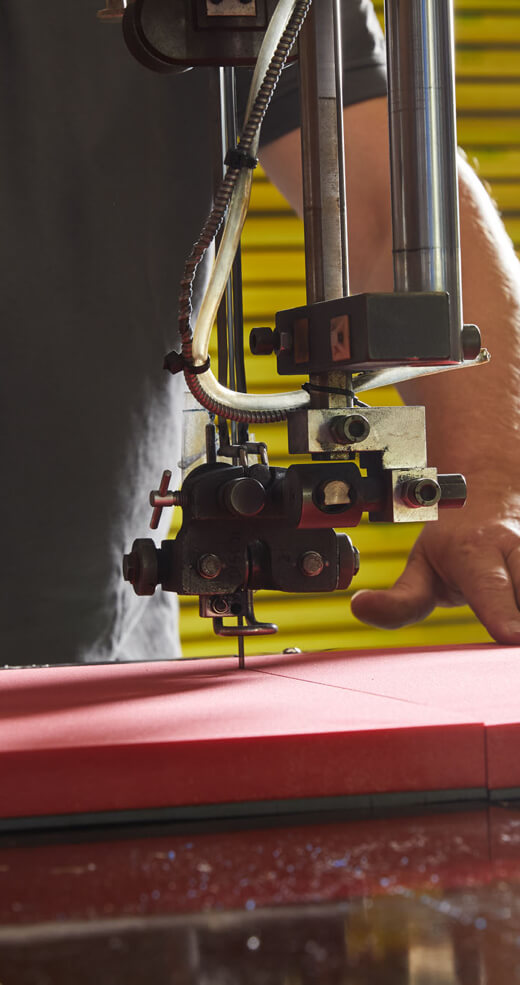

Fully Digital

Our production operations are now almost fully digitalised, which works to the benefit of our customers. For example, our impressively short production times enable us to meet all the latest inventory reduction and just-in-time delivery requirements.

Our advanced laser technology opens up opportunities for organisational elements and personalisation. Details such as workstation IDs, article numbers and serial numbers can be laser-etched anywhere on the surface of the inserts in various font styles and sizes. Logos and pictograms are also easy to add.

Ecologically Aware

We differentiate between chemically and physically foamed plastics.

The material we use most is foamed using a vacuum process, which makes it the most environmentally friendly option of its kind. PE and POM are ideal for environments where work needs to comply with hygiene standards, such as the food industry. We process these materials, too.

for Production and Logistics

in the Smallest of Quantities

April 2023

The number of milling machines grows to 28.

August 2023

TECSAFE expands their capacities for individual layout labelling via laser engravings.

December 2022

In cooperation with leading tool manufacturers, TECSAFE now offers individually configured foam layouts to consumers.

October 2022

The semi-automated production street is complemented by a third cutting machine.

July 2022

In connection with the first partial automation, another robot will be installed for a self-sufficient production line.

December 2021

A new milestone in TECSAFE’s production processes is reached with the first robot in the production line.

January 2021

TECSAFE expands the machine park with a splitting and laminating machine, which means that customer requests can be addressed even more individually. Own material processing.

2020

Opening of the new logistics building

January 2019

Beginning of expansion of logistics area in Solingen by 400m². Production is also expanded and the machine parks grows to 26 milling plants and by a second automated cutting machine.

March 2018

Production is expanded and the machine parks grows to 21 milling plants.

November 2017

Production is expanded and the machine parks grows to 17 milling plants.

March 2016

Automated cutting technology is introduced. 10 milling plants.

December 2015

The company moves into its new headquarters on Dingshauser Straße in Solingen.

December 2014

The machine park is extended to 8 milling plants.

August 2013

Online Foam Configuration System 2.0 goes online.

March 2012

The machine park is extended to 4 milling plants.

April 2011

Developement work starts on Online Foam Configuration System 2.0.

July 2010

TECSAFE GmbH is established. 1 milling plant.