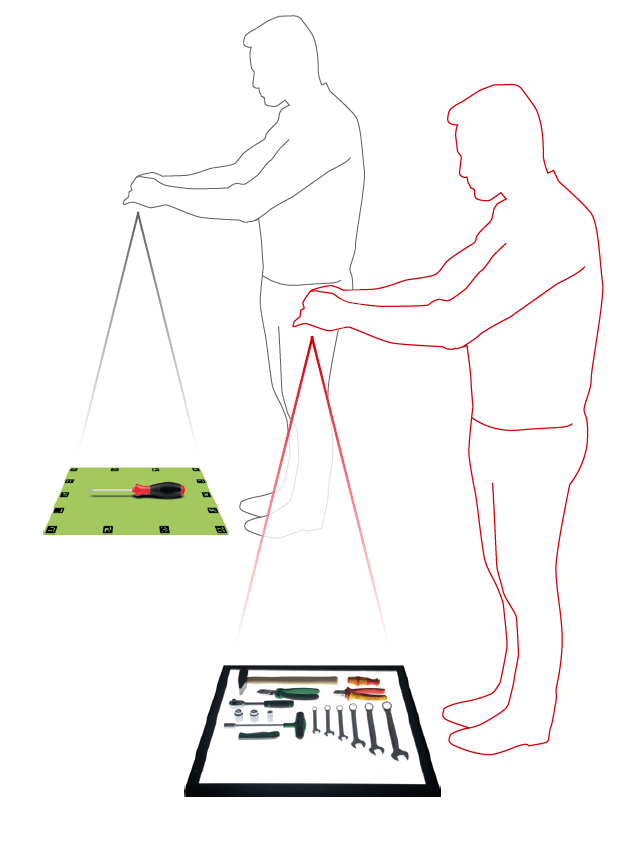

“The final product can only ever be as good as the contour data on which it is based.” – From manual contour creation and mobile scanning with a smartphone or camera to professional 3D scanning, TECSAFE offers technologies to obtain the most accurate results for every application. We provide our customers with all contour data in digital format in their very own catalogues for future insert planning. Our close links with manufacturing companies mean our customers benefit from the widest possible selection of contour data without needing to have the relevant tool to hand.

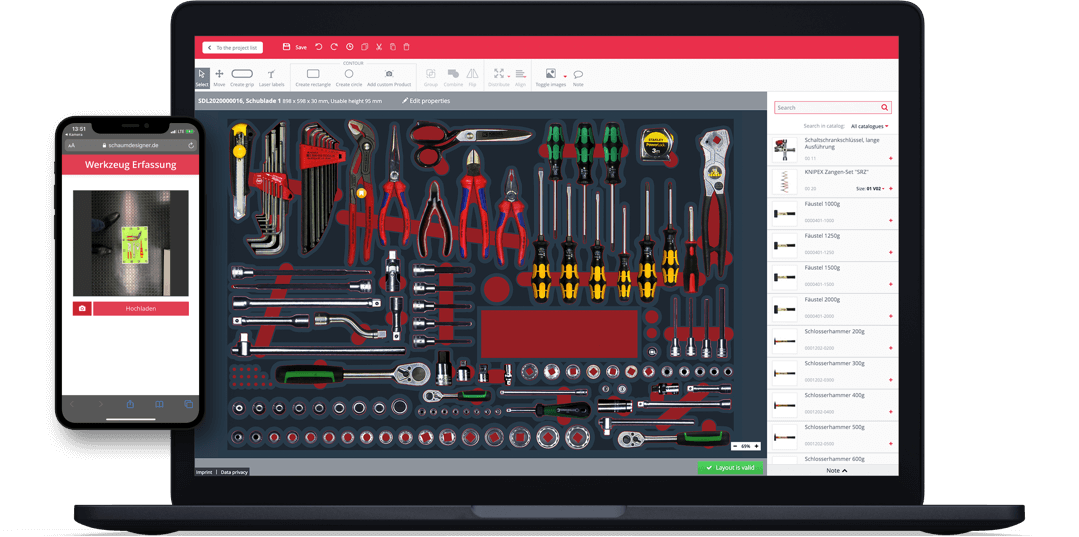

„Your Customized Foam – with the Largest Contour Database“

TECSAFE started out with the custom planning of foam inserts.

Our professional sales and engineering team offers our customers the advice they need to produce even the most sophisticated solutions.

Customers can also design foam inserts independently with our online foam configurator. Leveraging the experience of our engineers and customers in equal measure, it offers an intuitive interface for the self-explanatory creation of new inserts without having to compromise on professional details.

TECSAFE is ultimately all about high-quality foam inserts.

It’s the years of development work and the ongoing optimisation of our service operations that have made TECSAFE a leading manufacturer of top-quality foam inserts.

Our success is based on perfecting the entire value chain – from data and contour quality to our planning experience and actual production.

„Among classic, such as screwdrivers, our customers also protect other sensitive products with our high quality foam inlays – from knives, photo equipment and giftware to artifical dentition.“

„Together with our customers we explore ways for an economical production of customized foam inlays for the optimal storage of your valuable products.“

We have optimised and enhanced our production chain over the years.

Our production operations are now almost fully digitalised, which works to the benefit of our customers. For example, our impressively short production times enable us to meet all the latest inventory reduction and just-in-time delivery requirements.

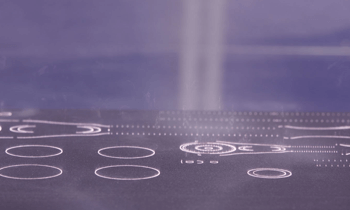

Our advanced laser technology opens up opportunities for organisational elements and personalisation. Details such as workstation IDs, article numbers and serial numbers can be laser-etched anywhere on the surface of the inserts in various font styles and sizes. Logos and pictograms are also easy to add.

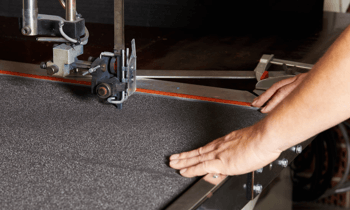

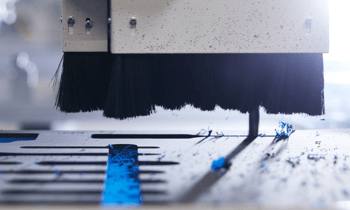

Custom Cutting

Our modern CNC-milling machines are the warrantor of our high quality standards and economical production. They work exclusively computer-controlled, fast and clean. All axis can be adapted individually to the different materials. We are able to mill foam up till 1.000 x 2.000 mm.

Contoure Cutting

The articles get custom-fit hold, narrow milling pockets are possible as well (from 4 mm caliber).

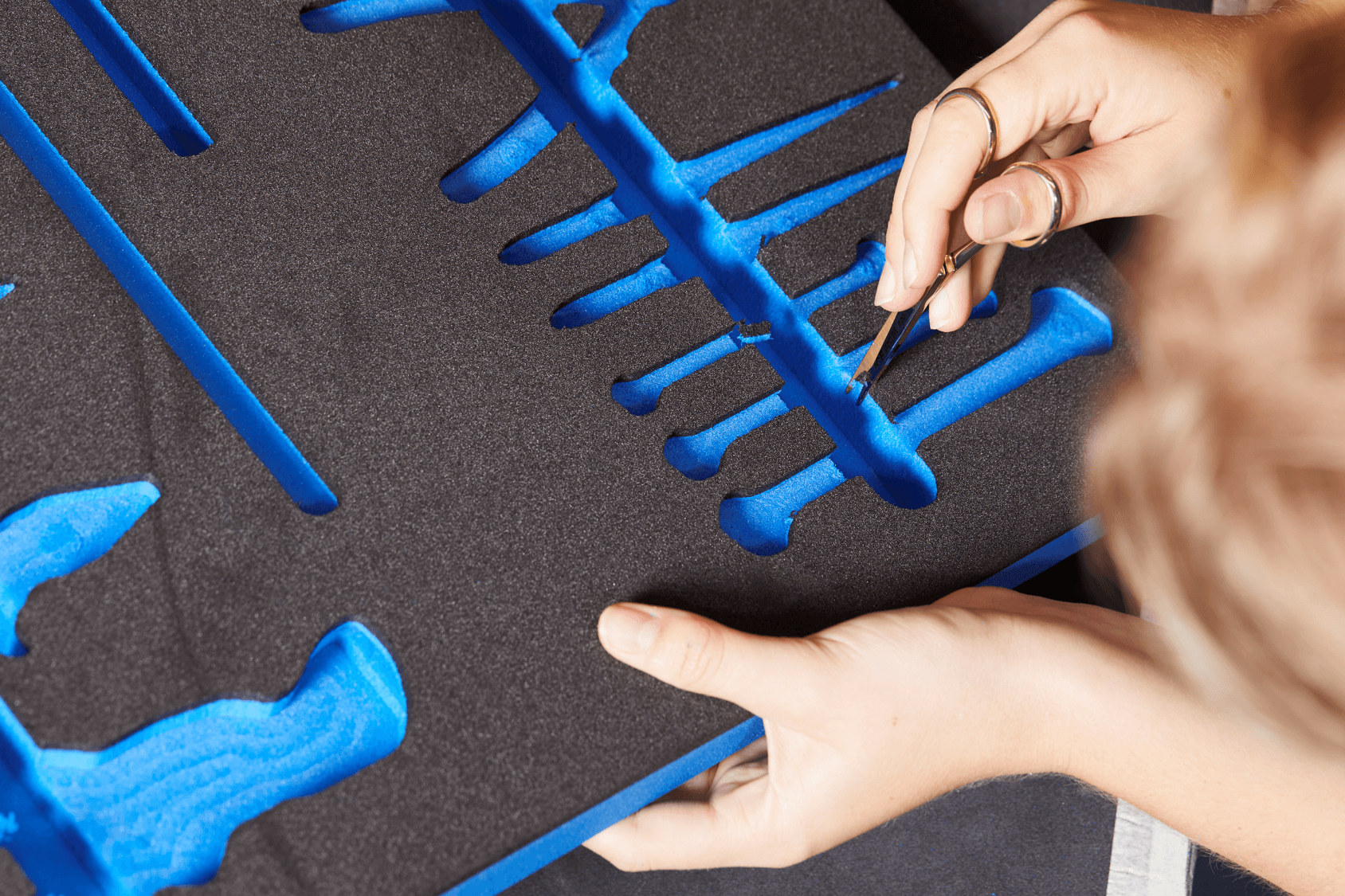

Post-Treatment

Each and every part is inspected for faults in production and it is only when they have successfully completed our quality checks that products are sent out.

Laser Engravement

To guarantee a better overview, we are able to laser helpful information on the surface of your foam,

Quality Assurance

Each and every part is inspected for faults in production and it is only when they have successfully completed our quality checks that products are sent out.